Overview

At Sci-Net, we aim to provide a positive learning experience internally as well as for our clients. Our aim is to extend our knowledge and experience to the wider community. We will be publishing regular articles and videos on all aspects of Business Central. This one is all about the Manufacturing and how Business Central can help to streamline this process.

Manufacturing is the production of goods through the use of labour, machinery, tools, and instructions. It can either mean the transformation of raw materials into finished goods on a large scale or the creation of more complex items by selling basic goods to manufacturers.

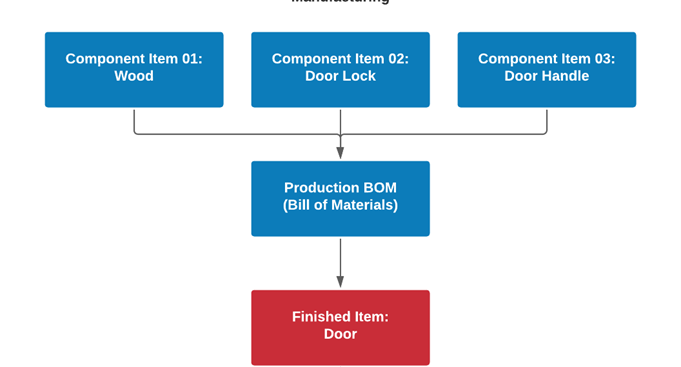

What are component items?

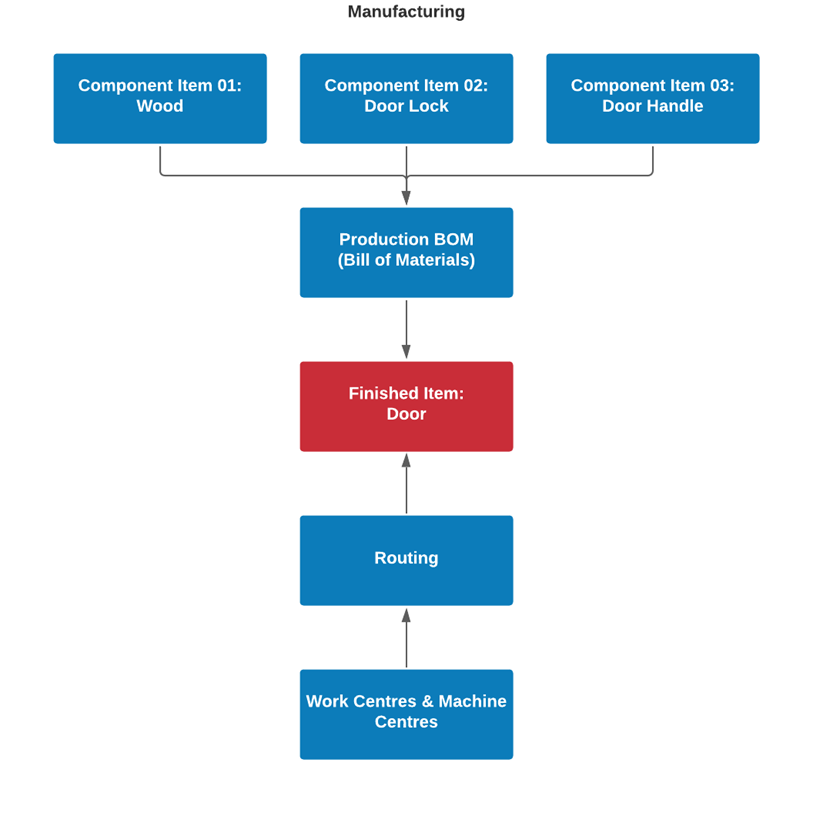

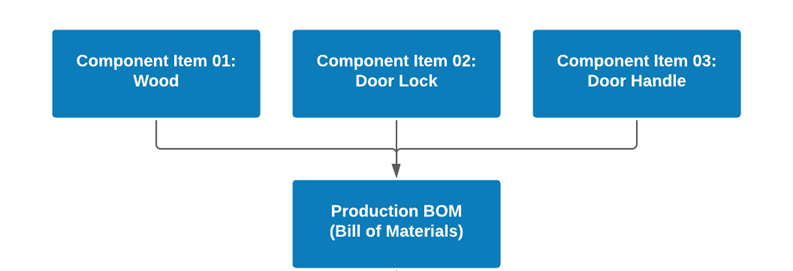

The manufacturing process starts with the creation of components items, which are classed as standard items in business central. Each component item has its own item card and the ability to be held on stock in its raw format.

For example, if a door manufacture produces doors internally, they will need to stock all the raw components needed to make a door. Not only will these be useful as component items in a production bill of materials (BOM) – but they may also be useful if the door parts become rusty and need replacing.

What are production BOMs?

Production BOMs represent the component items that are necessary to produce a finished item. In the scenario provided earlier, all of the raw materials necessary to produce a door should be grouped together in a production BOM.

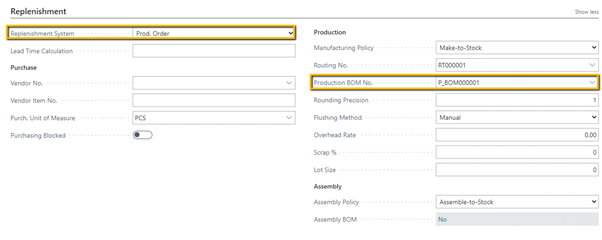

Eventually the production BOM should be linked with the item card associated with the finished production item. This will instruct business central that any execution of the production BOM should lead to the inventory count of the associated item increasing. To do this the replenishment system on the appropriate item card should be set to ‘prod. Order’, and the production BOM no. should contain the number of the production BOM that’s used to create the finished item.

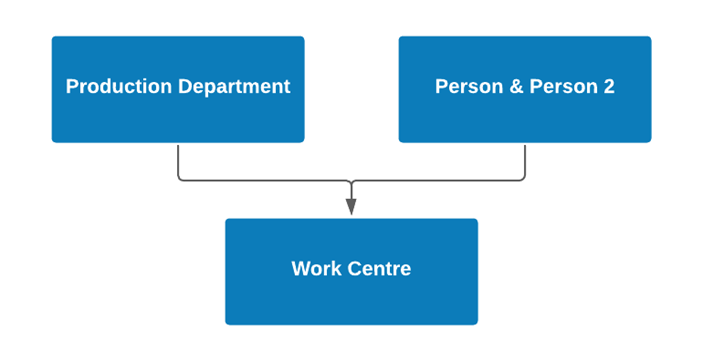

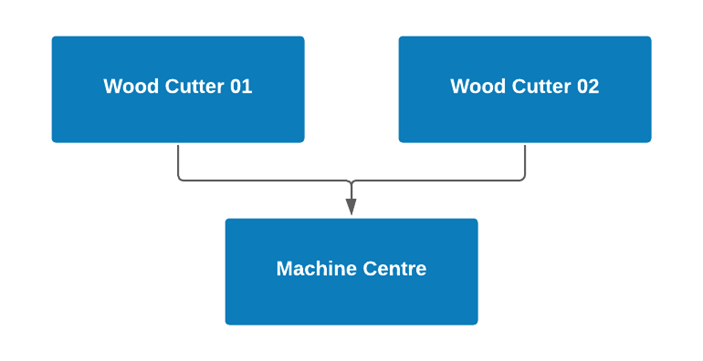

What are work centres and machine centres?

Work centres and machine centres can be thought of as placeholders that represent the departments and machinery required to put the raw component items together.

Work centres typically represent the departments and people that are used to either administer the production process, or control the machinery that merges the raw materials together.

Whereas machine centres represent one or more machines that perform a specific task, such as the cutting of uncut wood to create a door.

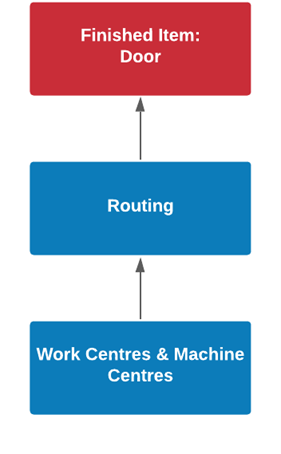

What is a routing?

A routing is a set of instructions detailing how a finished item should be created. It will state the work centres and machine centres that are necessary to merge raw materials together and will include the time it takes each work centre/machine centre to complete their given task, as well as any necessary cool down time that may be required between the different routing operations.

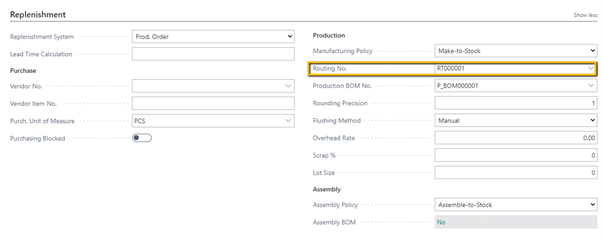

Once a routing has been configured, it should be linked to the item card associated with the finished item. By doing this business central will know that when a production order is created for the production item, the routing should be used to put together any raw materials stated in the production BOM. To do this the routing no. field should contain the number of the associated routing.