At Sci-Net, we aim to provide a positive learning experience internally as well as for our clients. Our aim is to extend our knowledge and experience to the wider community. We will be publishing regular articles and videos on all aspects of Business Central. This one is all about Production Orders and how Business Central can help to streamline this process.

Overview

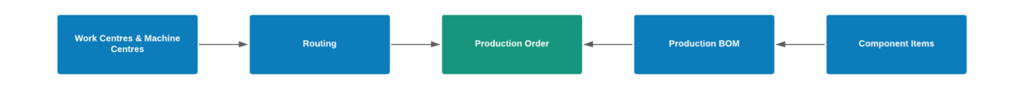

In business central, production orders are used to manufacture component items into finished production items. These orders will take information from different areas to gauge the components needed to produce the finished production items, the instructions necessary to put those components together, and the work centres/machine centres that are used to help fulfill those instructions.

Production orders are also split by their status – with each status representing a different point in a production order’s lifecycle. More information on this can be found in the following section.

What are production order statuses?

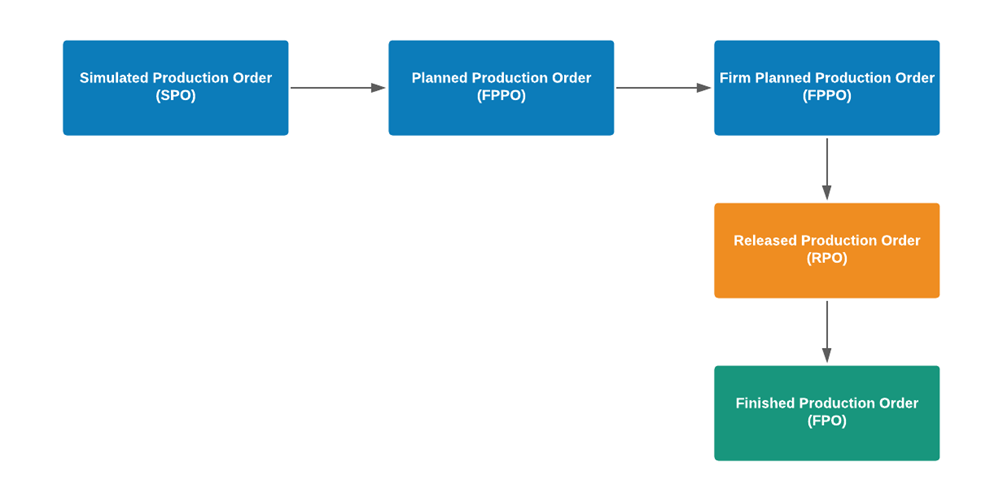

Business central makes use of 5 different production order statuses, with each one used to distinguish where a production order is situated along the production order lifecycle.

Production orders can start with either a simulated, planned, or firm planned production order status.

Simulated Production Orders: This production order is used for costing and quoting purposes – and can be progressed to a planned production order if appropriate.

Planned Production Orders: This production order status is typically used when a production order is created but there isn’t a firm commitment that it will be progressed and produced. Planned production orders will also progress to firm planned production orders once a firm commitment has been made.

Firm Planned Production Orders: This production order status is used when there’s a firm commitment that a production order will be progressed and produced.

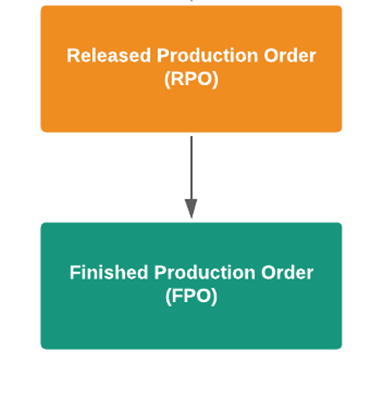

Once a firm planned production order is released for manufacturing, it will progress to a released production order. Orders with this status differentiate from firm planned production orders because they allow users to post the consumption of component items, work centres, and machine centres.

After a production order has consumed the relevant components and recorded the finished item as an output, it can be progressed to a finished production order. This status implies that a production order has finished – and consumptions can no longer be posted against it. It is also crucial that production orders are progressed to this status to update the necessary G/L accounts.